ECO Green Equipment’s tyre recycling machine yields 50% more crumb rubber with less power.

Eco Green Cut Crumb Costs

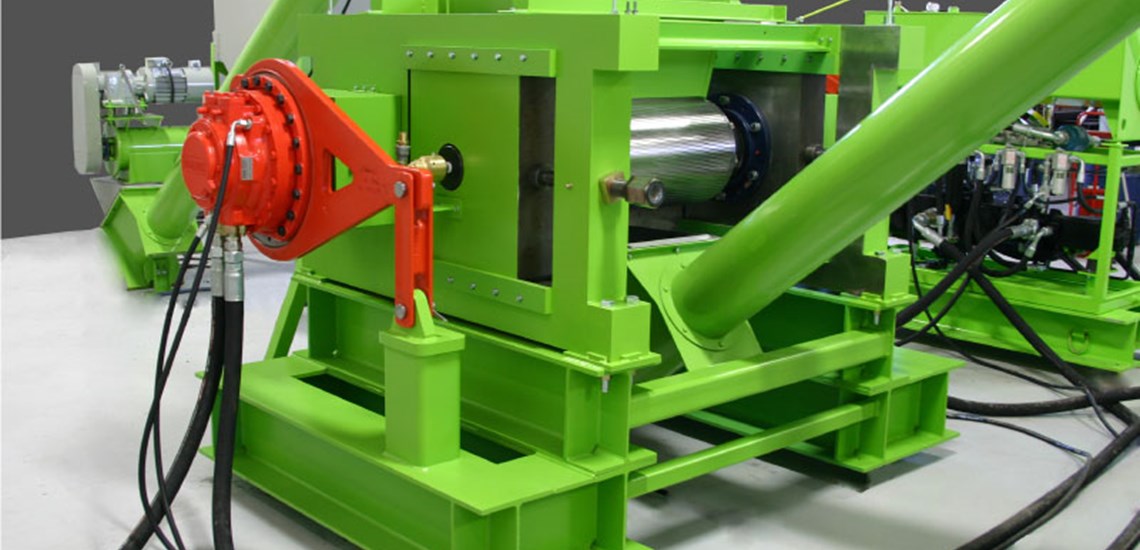

ECO Green Equipment produces turnkey industrial tyre recycling solutions to help companies turn old tyres into valuable aftermarkets. And as their revolutionary Krumbuster machine shows, they’re doing it in a way that’s cheaper, faster and more eco-friendly.

Like other cracker mills, the Krumbuster machine turns recycled tyres into crumb rubber that can be used in applications like artificial turf, pavement, and playground surfaces. However, the Krumbuster overcomes a common industry obstacle to achieve 50% higher output than the competition while using 35% less horsepower.

Cracker mills operate with two corrugated rolls that operate at different speeds to crush and grind rubber into crumb. Typical mills contend with a very narrow range of speed differentials (also known as friction rations), which limits their ability to turn out sufficient quantities of crumb across their full range of speed. It is a well-known industry problem that, up until now, has lacked a good solution.

According to Eco Green, the Krumbuster has reinvented the process, using hydraulic pumps instead of mechanical gearboxes. The hydraulic power allows the machine to respond quickly to variations in friction ratios, high shock loads and constant pressure changes. As a result, it delivers full torque at all speeds while using less energy. It also requires much less maintenance due to the fact that it can be started under load. This negates the need to clean the rolls out before starting the machine.

The Krumbuster was recently praised by Parker Hyudraulics & Pneumatics for “streamlining” tyre recycling through its added “reliability and responsiveness.” Brad Swenson, President of ECO Green Equipment says; “Our goal is to help companies turn over the maximum amount of rubber with the minimum amount of energy, and we’re constantly innovating ways to do this better.”