EcoTech’s process is non-toxic and produces an Active Rubber from waste rubber. “Rubber is a valuable commodity, and we are making it reusable,” says CEO and President Gideon Drori. “AR is a substitute for synthetic rubber that can be used to make new tyres, automotive parts, or an inner wall and flooring insulation called ECOINSUL that we developed ourselves.”

Israeli Firm Claims Ground-Breaking Technology

ECOINSUL, Drori says; “is literally a new standard that outperforms the current standard 10-fold. There is almost no difference in price, and it is easy to handle and apply. It makes for a remarkably effective acoustic and thermal insulation.”

EcoTech completed its testing and upscaling in early 2020 and has already signed a partnership with Austrian based Sibur International, a synthetic rubber manufacturer. The process holds some 21 patents around the world.

“Sibur has brought us a lucrative contract in the Austrian market and may set up its own factories using our technology,” says Drori.

“We are in discussions with a large chemical manufacturer in Italy and we’ve been asked to set up factories in the UAE. We have also been approached by Russia, China and Australia. And we hope to set up another facility in an OECD country.”

EcoTech is raising capital and converting its R&D site in Acre (Akko) into a factory to fill orders.

Drori explained that the EcoTech patented technology uses 95 per cent less energy than traditional rubber production processes.

“With increased oil prices and toxic contamination, the rubber industry is critical when it comes to reducing environmental pollution,” he says.

“AR is produced without hazardous oils, chemicals or new resources. It is such a clean process that for every ton of AR we produce we get 6 tons of carbon credit. The idea of the circular economy is completely coming to life and in a manner far better than putting waste rubber back on the market.”

Drori points to the proposed EU ban on microplastics and says; “This brings a problem of how to handle waste rubber from tyres into a new sphere, because existing solutions such as devulcanisation, combustion and burning tyres for fuel are environmentally problematic.

“We are one of the only solutions out there that is completely viable and ready,” he says.

The company’s technology is based on an idea of the father of its chairman and founder, mathematician Oleg Golobrodsky.

“Oleg was introduced to me in 2005. His father had been the COO of a large ammunition factory in the Soviet Union… his legacy was a crazy idea of how to recycle tyres,” Drori explains.

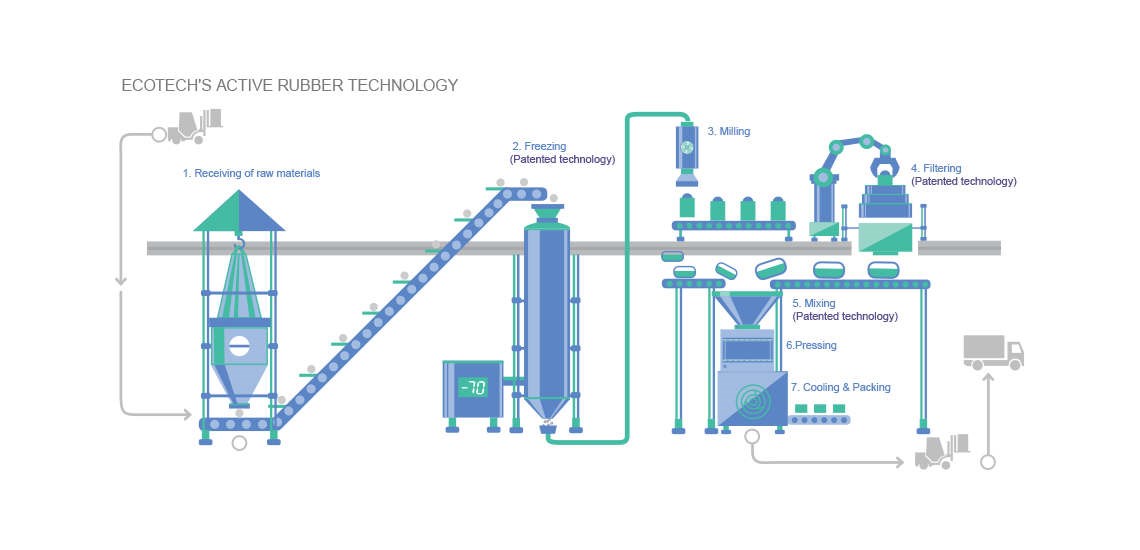

“Oleg and I set up a company in Ukraine, and in 2011 brought it to Israel and started to work on Oleg’s father’s idea — a thermodynamic technology that freezes rubber without a lot of electricity and no liquid nitrogen and turns it into micron-sized powder.”

Working with experts from the Technion-Israel Institute of Technology, the EcoTech team led by Chief Engineer Oleg Zuikin developed a chemical process that reactivates the polymers in the micron powder, enabling them to connect to other polymers and form a new material.

“We can take any kind of used tyres and turn them back into synthetic rubber. We are the only company in the world that has closed the loop on used tyre recycling,” claims Golobrodsky.