Modern Recycling Factory (MRF) was founded in Qatar in 2012, by Mr. Abdulla Salem Al Ali, to deal with the growing waste tyre issue in the country

The factory is situated in the heart of the industrial zone over 20,000 square metres in Messaied City, Qatar. Modern Recycling Factory (MRF) makes the most efficient use of research and technology development qualities, wider and wholesome clientele, and enhanced large-scale facilities. All acquired and strengthened as a result of the management integration, enabling them to proceed in improving and developing their products with high-quality International (ISO), American (ASTM), and European’s (CEN) standards in various fields and several applications that will be a replacement for resources such, as concrete and asphalt.

The vision behind choosing the tyre recycling business was to meet the Qatari Government’s efforts to save the environment, and helping to achieve the national vision of Qatar 2030.

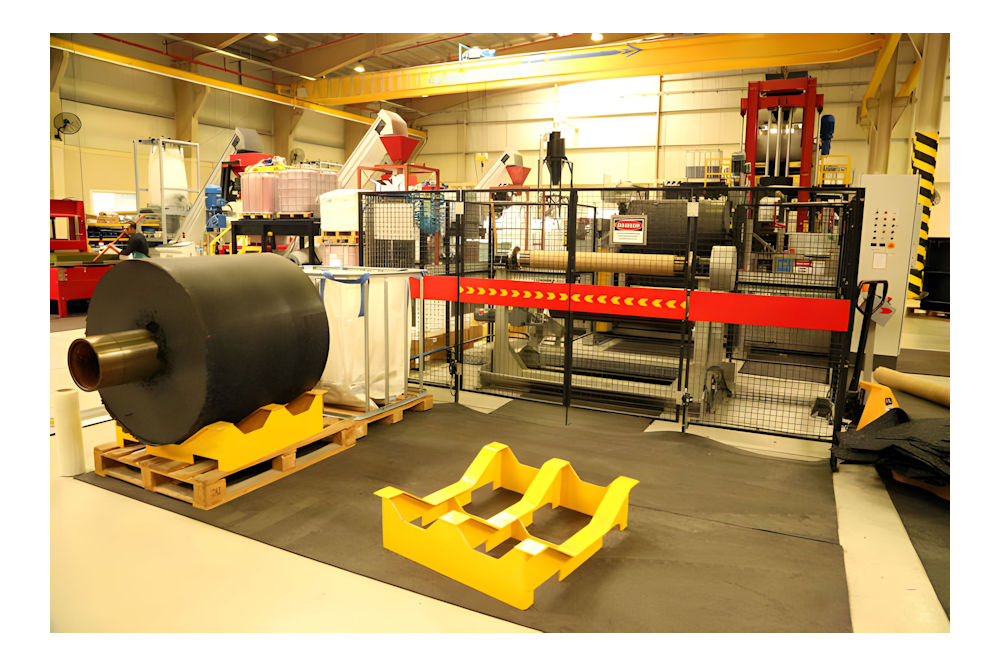

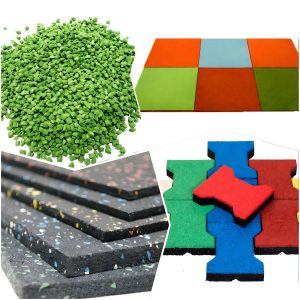

MRF, across three lines of tyre recycling, produces 75 tons per hour of rubber crumb, steal, and shred. MRF aims to be the premier provider of recycled tyre rubber products not just in Qatar but in the whole world. By recycling more than 1.5 million of the nation’s ELT out of the current 35 million awaiting recycling at several sites within Qatar; the factory transforms them into raw materials for smart, sustainable products that improve peoples’ lives, such as sport fields, running tracks, playground, buildings, infrastructure, and matting surfaces.

With quality project management, innovative tools, technologies and processes from European technology, MRF is already a revolutionary Qatari environmentally friendly enterprise. The factory’s commitment in finding modern and better ways to Reduce, Recycle and Reuse waste tyres, meets the sustainability goals of Qatar’s National Vision 2030.

MRF products are tested and accredited by certified laboratories globally, such as SGS and others. They use TRIAX 2015 for the surface impact system. These tests are to assure clients that they only offer highly quality goods that are equal to international safety standards. Across its full product range, MRF ensures exceptionality and client satisfaction in all the craftsmanship they make.

MRF’s aim is “To be the premier provider of sport flooring, building infrastructure, playground, fitness and gym’s products not just in Qatar and the GCC, but worldwide”.

MRF’s core values define the philosophy of Board of Directors, and they reflect the best of the organisation’s character. They provide the highest training for the staff; they also tend to share the products’ examination with the most reliable international laboratory tests to reach an outstanding product quality.

Since MRF includes the largest tyre recycling lines to manufacture rubber crumb, this gives the highest strength to the downstream technology to produce many products under one roof.

MRF markets its products locally and internationally, this is why it has two sales teams for local and export sales, each of them having their own tasks. They make their approach through many marketing channels, by personal visits and the use of social media, also through the participation in tenders, according to their spokesman, the annual target has always been achievable and even during the pandemic period, the percentages of the achieved sales were relatively high compared to the sales target.

Mr. Abdulla Salem Al Ali, Chairman of MRF believes in the commitment to provide customers with the premier service at a cost-effective price. “We are continually finding new ways to reuse and recycle scrap tyres to stop them going to landfill areas. Recycling tyres is MRF’s commitment to the environment. We will achieve a healthy and safe environment that contributes to accomplishing the national vision of Qatar 2030 and the world environmental vision” added Abdulla.