At Jack’s Landing in New Zealand, Water Smart laid 207 square metres of Porous Lane, a rubberised paving developed by the University of Melbourne

Klaudia Matyjas, business development manager at Water Smart, said that the first small section was installed as a mixer test before the full trial, describing it as a “big milestone” for the Australian-based company, which has been developing the product for local conditions since its arrival, Waikato Times reports.

The paving uses rubber processed by Treadlite under the national Tyrewise scheme. Treadl8ite was originally founded to address tyre waste in Cambridge, and now it collects tyres across much of the North Island. Blacke Richardson, Executive Director, said that truck tyres are preferred for the paving since they contain less fibre than car tyres, which makes them more suitable for processing.

Each square metre of Porous Lane can contain up to three tyres, and the Hamilton project used around 170 passenger tyres. Matyjas said the product cures within eight to 12 hours, has a 25-year design life and is softer and smoother underfoot compared to concrete. She described it as a “premium product,” noting that, even though it costs more than conventional paving, it offers additional benefits.

The paving is designed to be more permeable compared to standard footpaths, which allows water to soak through to the ground, reducing strain on stormwater systems. University of Melbourne studies also highlight that it can capture contaminants, preventing them from being washed into waterways. Matyjas explained that the material’s high porosity, about 40%, makes it suitable for sites where tree roots can damage conventional paths.

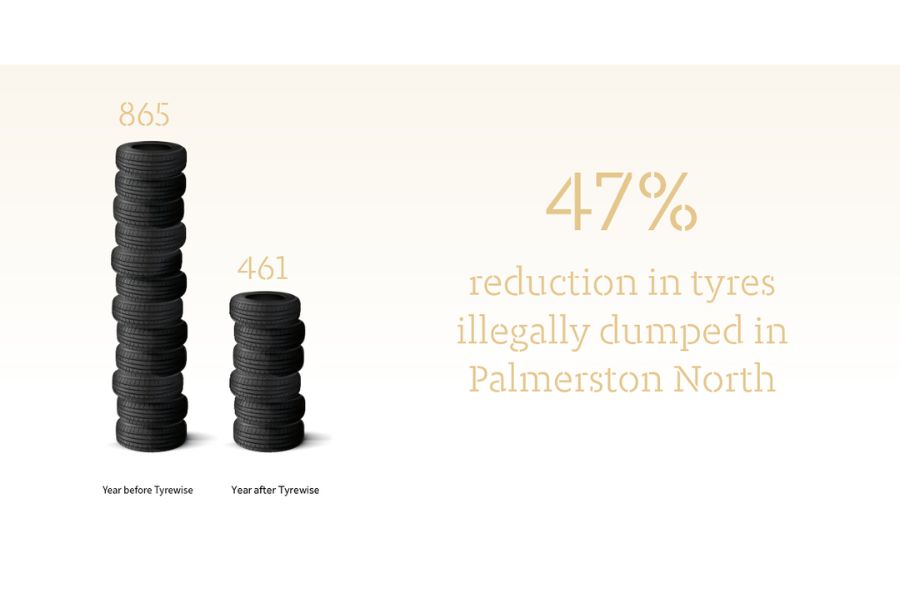

Kiri Speirs, marketing and communications manager at Tyrewise, explained that the scheme was established in response to pressure from the tyre industry for regulation. About 6 million tyres reach the end of life annually in New Zealand, and until recently, only 40% of these tyres were recycled, while the rest were stockpiled, landfilled, or dumped illegally. Tyrewise has been collecting tyres since September 2003 and aims to ensure that 80% of tyres are onshore by its fourth year of operation, which will require innovation and partnerships. Researchers in Canterbury are also testing ways to use recycled rubber to build foundations that will improve earthquake resilience.