Fernite of Sheffield Ltd is an award-winning UK manufacturer of machine knives and precision ground steel products. For almost 200 years Fernite has manufactured bespoke and specialised machine knives to serve customers across a wide range of industries.

Fernite Reassures Market with Blade Supply

Fernite is an ISO9001:2015 certified company, committed to quality management in everything it does. Operating from modern production facilities, the company always works to customers’ individual requirements. It is investing heavily in the latest computer-controlled precision machinery and 4IR tech.

For several years Fernite has been offering machine knives to the tyre and rubber industries. All made in Sheffield by a highly skilled workforce. To increase their market share of the recycling business, Fernite recently acquired Mastercut Cutting Systems Ltd – a world-famous producer of granulator, shredder, pelletiser, and circular knives for tyre recycling machinery. This strategic expansion extends Fernite’s production facilities and increases its market share of this business.

Now Fernite supports the world’s most popular brands in the tyre and recycling industries. Having several contracts with the local recycling facilities, the company has been steadily growing in recent years. Fernite also has customers who recycle rubber for many other industries including building, flooring, gardening & electricity. Most of these customers use standard rubber cutting machines to produce different kinds of rubber crumb. By developing bespoke solutions to solve each individual customer’s cutting problems and issues, Fernite’s expert team take on the cutting challenges that other machine knife companies will not attempt.

“People appreciate personal support, and we are happy to be with them from manufacturing through to operational stages”, – said Fernite’s Managing Director James Kitching. Fernite always seeks dialog with its customers to improve modifications of the machine knives. Engineers at Fernite manufacture and supply rubber and tyre recycling blades that are designed precisely for each cutting application.

Matching operational machinery blades with a processing material is one of the major factors determining the efficiency of a recycling process. Tyres are made of approximately 80% rubber compound, so for both tyre and non-tyre rubber scrap, the material recovery technologies are usually the same. As granulators, shredders and pelletisers are amongst the most common machinery in any rubber scrap yard around the globe, Fernite provides a wide variety of common and specially designed knives for them.

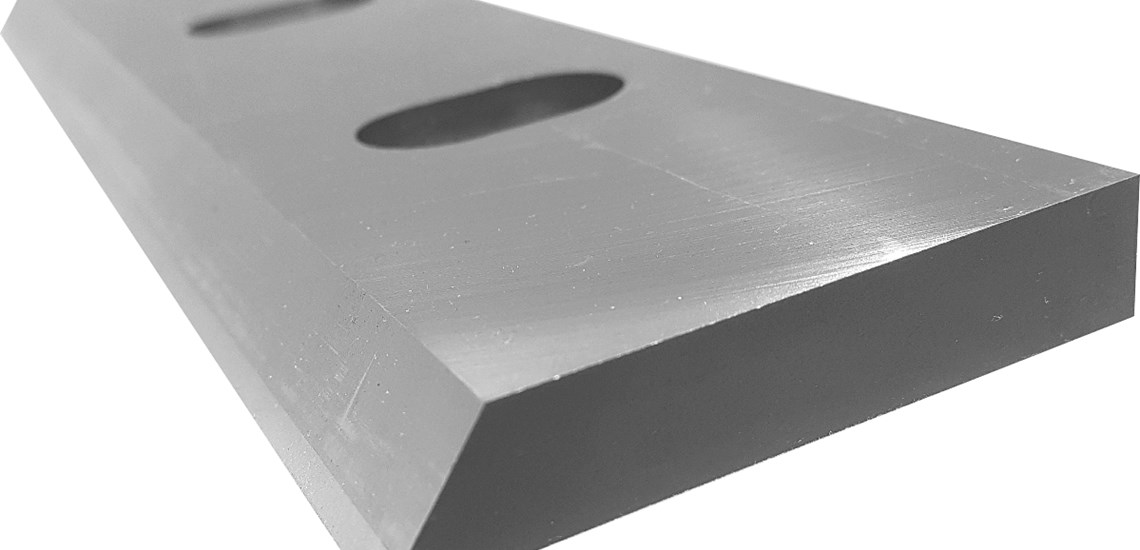

Fernite offers a wide range of granulator blades for the rubber converting and recycling industries. Fernite offers a large range of stationary (dead) and rotating (fly) granulator knives and blades in a wide range of popular and custom-made designs for the tyre and rubber recycling, manufacturing, and converting industries. Fernite supplies granulator blade for Bruno, Conair, Dragon, Erema, McIntyre, Tia, Vecoplan, Zerma machines and more. Edwards, Rapid and Cumberland granulator blades are among the most popular from their large range.

The factory manufactures granulator blades in various steel grades:

- High Carbon High Chrome to improve hardness, wear and corrosion resistance.

- High Speed Steel to withstand heat created from the friction of rubber.

- Tungsten Carbide Tipped for being sharp, durable, and able to sustain high loads.

- High Alloy Tool blades with the adjusted balance between hardness and toughness.

To improve even further wear resistance and mechanical burdening of knives and blades, the company has started manufacturing not only from standard steel grades, but also from innovative steel grades and alloys.

Fernite also manufactures and supplies single shaft shredder blades that fit to a variety of tyre shredding machines. Fernite also offers heat treated shredder blades with hardness within 40 to 70 HRC according to customer needs. Also, Fernite produces a vast range of pelletiser blades with single and double bevels, various number of holes and slots.

With the product range expanding Fernite are recruiting new team members and now have outgrown their current facilities. In the beginning of this year Fernite announced a move to a new purpose-built £1.8m factory! This great project demonstrates Fernite’s business strategy to improve their support to customers by increasing stock, accommodating more machinery, and increasing turnaround times.