Nanografen, a nanotechnology R&D company and Graphene Flagship partner founded in Turkey in 2013, is finding clever ways to recycle old tyres into graphene applications.

NANOGRAFEN was established by scientists from Sabanci University and Inovent Company which is a seed fund company, a fully owned subsidiary of Sabanci University.

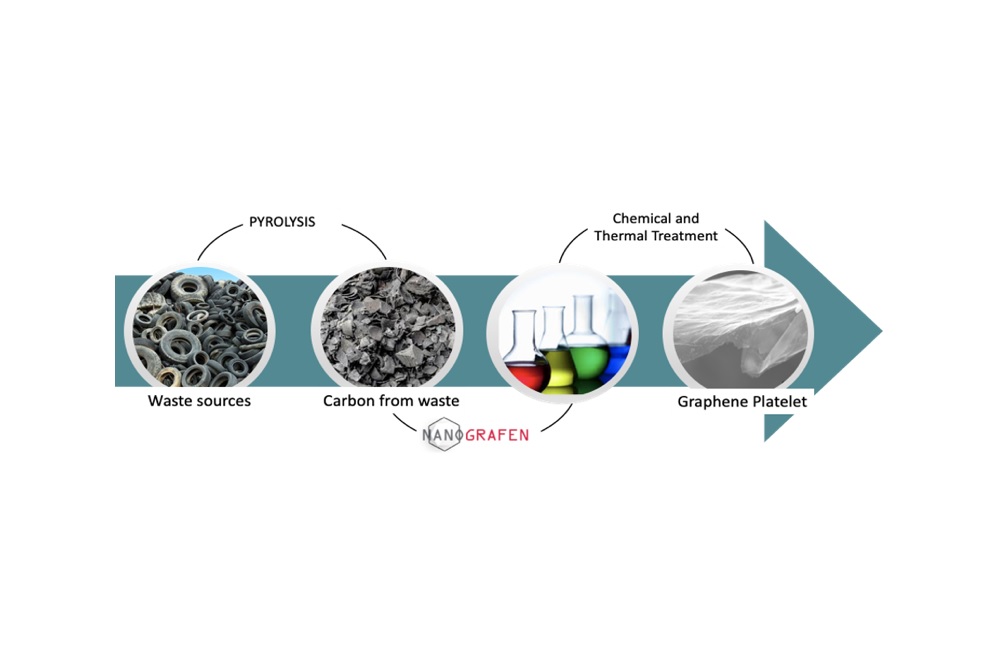

Nanografen lowers the cost of graphene by using waste tyres as a starting material by applying recycling and upcycling technology for mass production in plastic industry. Nanografen has a partnership with one of Turkish Pyrolysis Factories (GAN Pyrolysis) and established a pilot production line in Biga Organized Industrial Zone/Canakkale with the capacity of 2 ton/month.

Nanografen Co is believed to be the only company that produces graphene from waste tyres in an industrial-scale around the world. Also, Nanografen is developing cost-effective and light-weight automotive plastic composite parts with the cooperation of Renault. Nanografen is an official material supplier of Renault, and together with Ravago and they developed OEM-certified masterbatch to reduce glass-fibre and mineral amounts in polypropylene-based interior and exterior parts.

By producing graphene from tyres, Nanografen lowers the cost of graphene. By applying recycling and upcycling technology for mass production in the plastic industry – is cheaper than many other forms of graphene production.

Nanografen’s repurposing of waste tyres creates a market opportunity. Conversion of waste tyres to recycled carbon black, to graphene, leads to possibilities for graphene to become an impactful part of the thermoplastic composites market. Thermoplastic composites are used across all sorts of industries, including aerospace, textiles, automotive, construction, energy storage, renewable energy, and flame retardants.

Graphene-reinforced lightweight automotive parts mark an exciting development for the automotive industry. These parts are cost-effective and also lightweight enough that they help reduce vehicular weight overall, thereby reducing the amount of energy or oil needed to power the vehicle. In this sense, their use in vehicles makes these vehicles more eco-friendly.

Nanografen is already being recognised for its innovative work. At JEC World 2023 in April, Nanografen was among the finalists for the event’s prestigious Innovation Awards.

Other Nanografen-based products under commercialisation include a graphene-reinforced recycled washing machine pulley and graphene-reinforced flexible polyurethane foams for sound insulation.