MMG’s Dugald River underground zinc mine 65 km north-west of Cloncurry in Queensland, Australia is tackling how to recycle End-of-Life (ELT) tyres, with an alternative to sending re-usable materials to landfill.

Devulcanisation for Mining Tyres

The mine annually generates about 920 ELT from vehicles and trucks. Currently Australia disposes of over 60,000 t of ELT tyres by exporting them. Some 100,000 t are stockpiled in landfill or onsite (mostly by the mining and agricultural sectors) according to global advisory firm, Energy Estate.

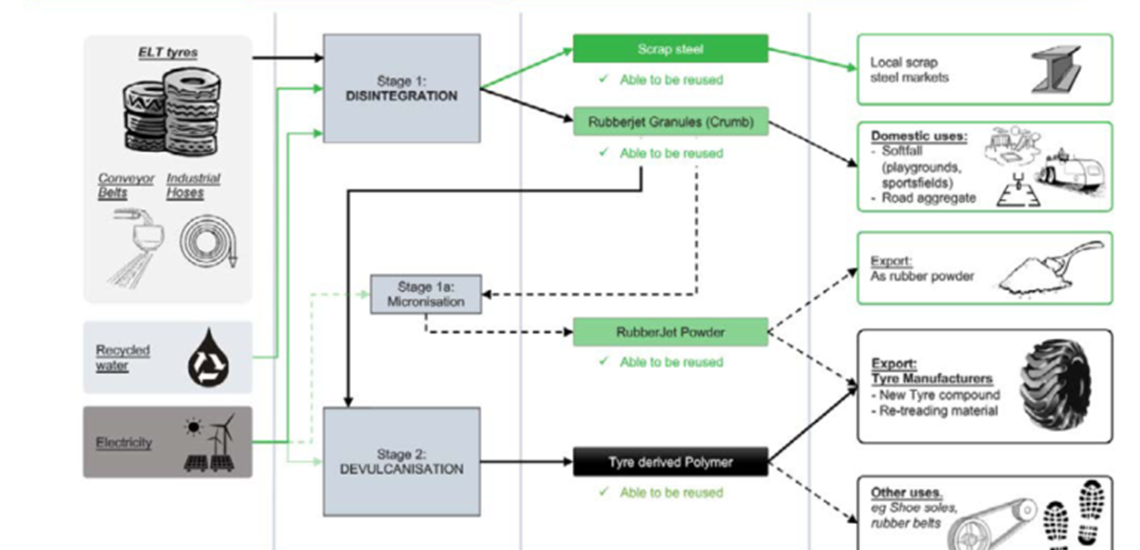

With the Council of Australian Governments’ agreed ban on used tyre exportation from December 2021, Australia faces a growing tyre stockpile problem. Dugald River and its mining contractor Barminco have investigated alternative tyre disposal, supporting a joint venture (REVYRE) programme with Energy Estate and InfraCo. A proposed recycling process breaks down and repurposes the tyres into a high value polymer product fit for tyre manufacturing and clean high tensile scrap steel.

The REVYRE recycling process “is chemical and solvent free with near zero waste and emissions or by-products making it an environmentally friendly technology.” REVYRE is also looking at renewable energy for its operations. This aligns with its low carbon footprint aspiration while reducing the environmental impact of tyre production. Barminco and MMG say they are proud to support this responsible initiative. A number of REVYRE plants are planned for each Australian mainland state supporting new jobs made possible from the development, construction and operation of the sites. The new plants have the potential to further reduce the carbon footprint burden that came with ELT being previously recycled in Victoria.

The Dugald River team has encountered some challenges with on-site ELT storage as it complies with environmental authority requirements. However, MMG says the team is committed to the smart recycling project and is also looking to reduce other waste streams such as single use plastics.

In the latest REVYRE newsletter from June 2021, the group says it has made considerable progress in the last six months in regard to its facility in the Mount Isa region of Queensland. There is an agreement in place with Economic Development Queensland to acquire to acquire the first Australian site. The site is located within the Nordale Industrial Precinct. REVYRE has received a number of Letters of Intent from major mining companies in the region who have agreed to supply feedstock to the plant once it is operational. The vision for the Mount Isa site, as a flagship for REVYRE in Australia, is that it will deliver on emissions-free solutions for the users of OTR tyres regionally and create re-skilling opportunities, training opportunities and new enduring jobs.

REVYRE has also been selected as a project for inclusion in Beyond Zero Emissions’ Renewable Energy Industrial Precincts (REIPs) proposal for the Hunter and Gladstone regions. The REIPs are designed to support domestic manufacturing opportunities and drive regional economic development through sustainable and renewably powered technologies. The REVYRE plant in the Upper Hunter region will be located within an industrial estate to be developed on the land currently occupied by one of the first coal mines in Australia.

The current sites will support local mining and industry operations and will generate employment and regional development for the local economies. The update highlighted current priority sites as Mount Isa, QueenslandHunter and Wollongong in New South Wales. Australian “pipeline” areas are listed as the Pilbara & Kalgoorlie in WAParkes, New South WalesPort Pirie in South AustraliaGladstone, Queensland.

REVYRE also has a NZ priority site marked as Tokoroa and a pipeline site as Whakatane.

REVYRE’s processing is based on the devulcanization technology developed by Tyromer Inc., which was founded in Canada and developed its technology out of the University of Waterloo. Recently, the European branch of the company Tyromer Europe (TyrE) announced its newest site in Arnhem, Netherlands.