When a tyre no longer guarantees safe and efficient performance to a vehicle, it becomes waste. It must therefore be collected for recovery and recycling, which takes place in special plants.

The treatment of end-of-life tyres has always been a problem in all areas of the world. From the most industrialised areas, where the presence of many vehicles determines the presence of large quantities of waste, to the more remote areas where, unfortunately, this type of hazardous waste is stored in large, abandoned areas with harmful consequences for the environment and the health of people.

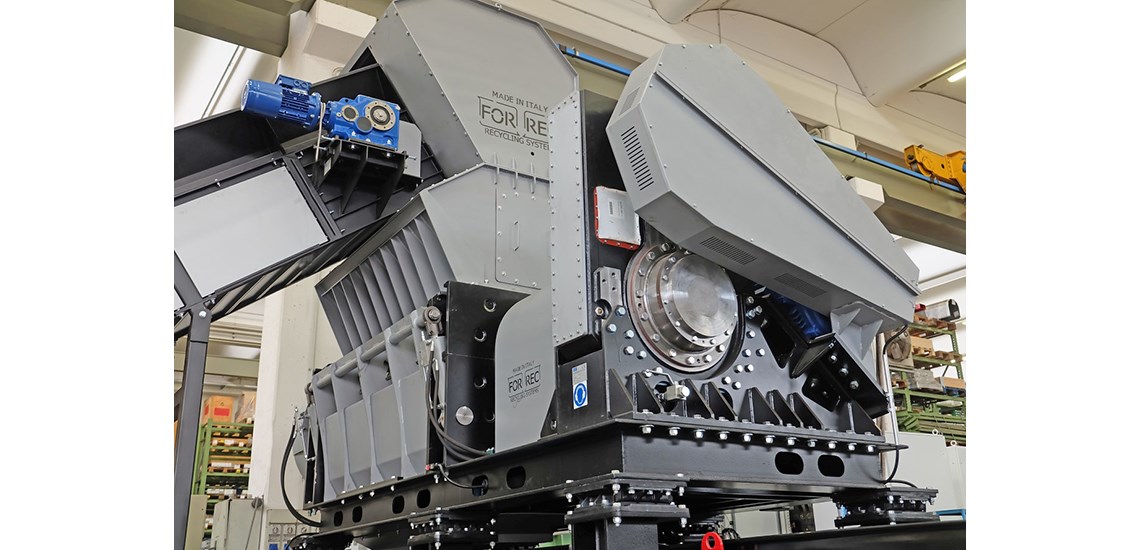

Forrec and the Treatment of ELTs

Thanks to Forrec systems it is possible to obtain a rubber granule with a size between 0.8 and 4 mm. This allows you to create innovative and eco-sustainable products that find application in very different sectors: from building products (e.g. panels for acoustic insulation and vibration damping) and for sports (e.g. football fields, multipurpose sports floors) to application for animal welfare.

Recycled rubber is also used in the building sector, where it is used in the production of asphalt, cycle paths, street furniture and elements for road safety, and in the creation of modern design objects.