REVYRE in Australia and New Zealand have stepped up a gear in the waste tyre sector, raising capital and partnering with Project Portfolio Management P/L (PPM).

REVYRE Signs MOU with Project Portfolio Management

The MOU with PPM brings a team with the right values, project management and operational capabilities in the mining and heavy industrial sectors to support REVYRE in accelerating and realising its strategy.

In 2020, InfraCo and Energy Estate announced the REVYRE joint venture – a partnership dedicated to addressing the global End-of-Life Tyre (ELT) disposal problem. Since then, significant progress has been made towards REVYRE’s first facilities in both countries and gaining support from potential feedstock providers.

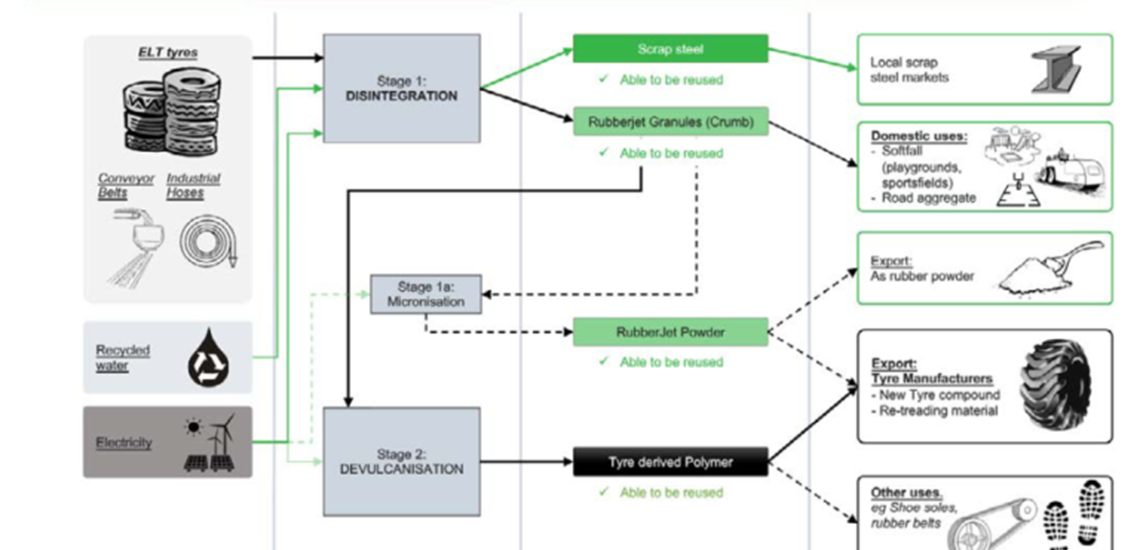

The REVYRE solution re-purposes 100% of tyre constituents by implementing a highly efficient circular process with near zero emissions, with no by-products and no toxic chemicals. The technology can disintegrate most tyres and recover the rubber compound and scrap steel for re-use.

REVYRE will focus initially on Truck-Bus-Radial and Off-the-Road tyres. The Tyre Derived Polymer (TDP), or rubber compound, that is created from the REVYRE process can be used to make new tyres and in general black rubber goods manufacturing. As the price of natural rubber continues to remain high and availability declines, TDP offers a viable alternative for manufacturers.

ELT disposal is an ongoing and growing global concern. No country is immune from the potential challenges of tyre disposal.

“REVYRE has entered the market at the right time to provide a global best practice solution to mining companies who continue to argue that burying or dumping tyres is the only viable option for them.” Shaun Zukor, CEO of REVYRE said.

“We now know the REVYRE re-processing solution is economically viable, environmentally sustainable and helps tyre manufacturers keep their costs in check as natural rubber demand and risks rise. This is good news for mining companies and provides a good incentive to stop dumping tyre waste at the expense of the environment and communities.”

CEO and Managing Director of PPM, Troy McDonald, said: “As someone who has worked across the resources sector, I know how important sustainability is to ensure a positive legacy and attract future investment. My team and I see REVYRE as a truly impactful solution and we are very excited to be a part of the company’s next steps in Australia.”

REVYRE has recently announced its plan to raise funds to support the roll out of several priority plants across Australia and New Zealand. The company is currently in discussions with interested parties and is hoping to achieve financial close for the first sites within the next 12 months.

“This is a great opportunity for REVYRE to showcase the innovative and sustainable solutions that exist for the mining and minerals processing industries.” Said Simon Currie, Principal at Energy Estate.

It is worth noting that REVYRE’s plans for tyre recycling and devulcanisation in Australia and New Zealand creates a replacement export potential as there is no viable demand for this recycled material in either country – they have no tyre manufacturing facilities. Unlike Tyromer’s Arnhem plant in the Netherlands, which has potential clients in Continental, Apollo, and other tyre manufacturers on its doorstep.