Recircle Awards ceremony combines in-person Award announcements with live streaming for the first time

Valebridge Media Services (VMS), the Crewe, UK and Madrid, Spain-based media services agency, has announced the winners of the 2023 Recircle Awards, the global industry awards event recognising sustainable innovation, production processes, management and services within the tyre retreading and recycling sectors.

The Awards were announced and presented to the deserving winners during a live ceremony conducted on 16 November during the Futurmotive Expo & Talks in Bologna, Italy. The ceremony was also streamed live to viewers around the views on the Youtube Channels of Media Partners Retreading Business and Tyre & Rubber Recycling, the leading global specialist publications for the global tyre retreading and tyre recycling industries.

David Wilson, Managing Director of Valebridge Media Services, commented; “We are once again delighted to have been able to celebrate the contribution made by the tyre retreading and recycling sectors to the Circular Economy and are pleased to report that over 6,500 individuals cast their vote in those categories that were open to the public vote. We once again saw exceptional engagement from all corners of the globe, and we congratulate the worthy winners of this year’s awards, who hail from as far apart as Colombia to Canada and from Italy to India.

“We would also like to express our gratitude to our main Sponsors Autopromotec, trophy designers Neusus Upcycling and to all our sponsors and collaborators for their kind support of the Recircle Awards,” he added.

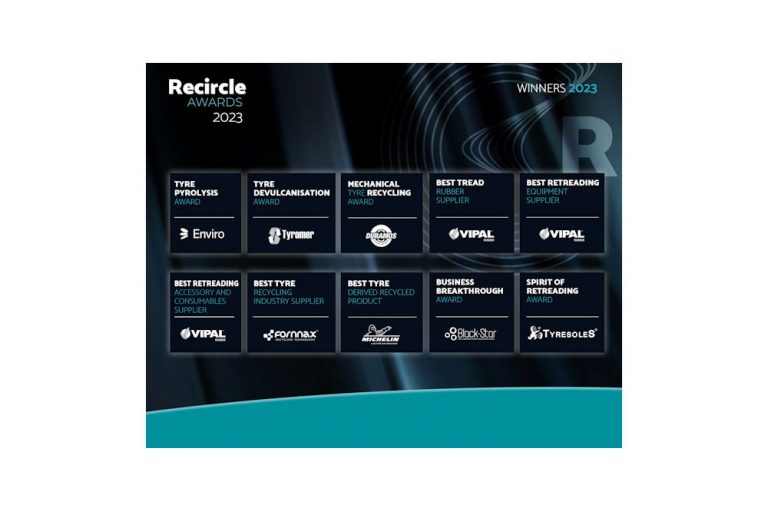

The winners of the 2023 Recircle Awards in order of their announcement were as follows:

- Best Passenger Retreader: FEDIMA

- Best Truck & Bus Retreader: MARANGONI

- Best OTR Retreader: MARANGONI

- Best EPR Scheme: VALORPNEU

- Best Tyre Recycling Research Project: BLACKCYCLE

- Best Tread Rubber Supplier: VIPAL

- Best Retreading Equipment Supplier: VIPAL MACHINERY

- Best Tyre Recycling Industry Supplier: FORNNAX

- Best Tyre Derived Recycled Product: MICHELIN

- Best Retreading Accessory and Consumables Supplier: VIPAL

- Tyre Pyrolysis Award: SCANDINAVIAN ENVIRO SYSTEMS

- Tyre Devulcanisation Award: TYROMER INC.

- Mechanical Tyre Recycling Award: DURAMOS SAS

- Employee of the Year Award: FABRICIO NEDEFF (VIPAL)

- Best Company Director: MATTHIAS LEPPERT (MARANGONI)

- Business Breakthrough Award: BLACK STAR

- Spirit of Retreading Award: TYRESOLES

- Industry Achievement Award for the Tyre Retreading Sector: PRESTI INDUSTRIES

- Industry Achievement Award for the Tyre Recycling Sector: REGOM

- Lifetime Achievement Award in the Tyre Recycling Sector: JEAN-PAUL BOUYSSET

Renzo Servadei, CEO of Promotec Srl, the organisers of Futurmotive Expo & Talks, commented; “The Recircle Awards have rapidly become the foremost awards event in our sector, celebrating the efforts of the many individuals and companies who have contributed towards raising the status of tyre retreading and tyre recycling as a significant contributor towards the sustainability of the tyre industry. It is entirely appropriate that this year’s ceremony was held at Futurmotive Expo & Talks, our new event focusing on sustainability, energy transition and innovation in the automotive sector.”

The fourth edition of the Recircle Awards will take place during Autopromotec 2025, which takes place in Bologna from 21-24 May, 2025.