As a leading rubber producer, Malaysia has, perhaps, not had a need for recycled rubber materials, but it does have a waste rubber challenge to address

On the 14th August questions were asked in the Malaysian parliament on how used tyres were being treated in Malaysia.

Datuk Haji Ahmad Amzad bin Mohamed asked the Minister of Plantation and Commodities to state:

(a) how the ministry is supporting the production of innovative products based on used tyres and developing the downstream rubber industry to transform this sector towards a circular and sustainable economy; and

(b) the incentives or strategic collaborations in place to strengthen research, commercialisation, and the use of these environmentally friendly products in the market.

Deputy Minister of Plantation and Commodities Datuk Chan Foong Hin responded in an extensive answer that clarified the current situation pointing out that Malaysia imported various types of tyres valued at RM3.53 billion in 2024 to meet domestic demand, which is estimated at 22 million units annually.

He added that the Malaysian Rubber Board (LGM) had taken steps through research and development to explore the potential of used tyres as a resource for a circular economy.

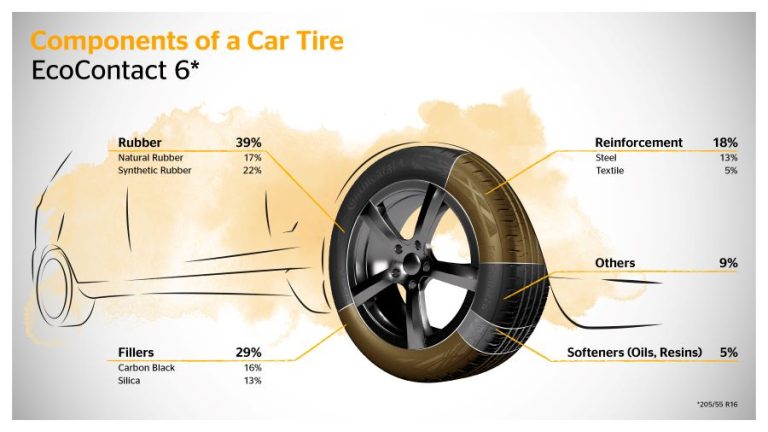

These studies included the use of recovered carbon black as a sustainable alternative to virgin carbon black.

There was also ongoing research into the uses of reclaim or devulcanised rubber and the use of recovered materials in alternate applications such as bitumen additives, brick production, road surfacing, rubber mats, and footwear.

He added that the Malaysian Rubber Council (MRC) has introduced a special fund under the Automation and Green Technology initiative to encourage rubber product manufacturers to adopt automation, digitalisation, and green technology.

The MRC also provides pre-commercialisation and commercialisation funding for innovative products through the Industry Linkage Fund 2.0 (ILF 2.0) and the MRC Commercialisation Fund (MCF), which includes funding for products derived from used tyres.

One innovative product developed through MRC funding is a new pre-cast wall panel, now undergoing pre-commercialisation trials with industry partners. This wall panel incorporates crumb rubber from used tyres, which enhances its resistance to heat, fire, and sound.

In a follow up question, Datuk Haji Ahmad Amzad bin Mohamed highlighted the benefits of Crumb Rubber Modified Asphalt (CRMA), which he claimed had been proven to improve the durability of road surfaces, reduce maintenance costs by up to 26%, and is environmentally friendly—as demonstrated on the SKVE Highway.

He then asked: “What is the ministry’s strategy to expand the production of high-quality crumb rubber, strengthen national standards, and promote the use of CRMA in both public and private sector projects, including developing export opportunities for this material?”

Datuk Chan Foong Hin responded that the MoPC through the Malaysian Rubber Board and MRC, is continuously working to enhance the rubber industry’s downstream applications.

On the issue of CRMA, the Minister stated that the government hoped to work closely with the Ministry of Public Works (KKR) to explore ways to implement this collaboration.

Khoo Poay Tiong the member for Kota Melaka then asked specifically about recycling, pointing out the reality that tyre shops found it challenging to dispose of their tyres.

He then asked if the ministry could adopt a whole-of-government approach, working with other ministries, to ensure all used tyres are collected and recycled? Tyre shop operators frequently complain that waste collection services refuse to collect used tyres, even though your reply shows they can be recycled and reused.

This point by Khoo Poay Tiong highlights the anomaly that local tyre arisings are left uncollected whilst Malaysia imported some 22 million units of ELT, according to the minister.

The Minister responded that the issue lies with regulatory oversight of waste management, which falls not under the Ministry of Plantation and Commodities but under the Ministry of Natural Resources and Environmental Sustainability (NRES).

It happens that there is a plurality of roles between the two ministeries and that gives rise to the possibility of an holistic approach to the problem.