Birla Carbon, one of the leading manufacturers and suppliers of high-quality carbon-based solutions, advises that its plants in the USA (Hickok) and South Korea (Yeosu) have secured ISCC PLUS certification with zero non-conformities

This accomplishment follows the successful ISCC PLUS certification of Birla Carbon’s plant in Italy, reflecting the company’s commitment to sustainability and circularity.

Birla Carbon’s Italy plant received the ISCC PLUS certification in May 2023, making it the first plant to receive this certification.

Commenting on this recognition, John Loudermilk, President and Chief Executive Officer, Birla Carbon, said; “We are proud to announce the ISCC PLUS certification for our plant in Hickok (USA) and Yeosu (Korea), marking another milestone in our sustainability journey. These achievements underscore Birla Carbon’s steadfast commitment to environmental responsibility. As we expand our certification efforts globally, with the rest of our locations, we are reinforcing our dedication to sustainable and traceable practices.” He further added, “Birla Carbon remains committed to setting industry benchmarks and contributing to a more sustainable future.”

Looking ahead, Birla Carbon is actively pursuing ISCC PLUS certification for several other global plants. The certification process for two units in Brazil and three units in India, Spain, Egypt, and Hungary is underway, with the remaining sites slated for completion through the remainder of CY 2024. The company remains dedicated to implementing sustainable practices, and this recognition reinforces its commitment to responsible operations.

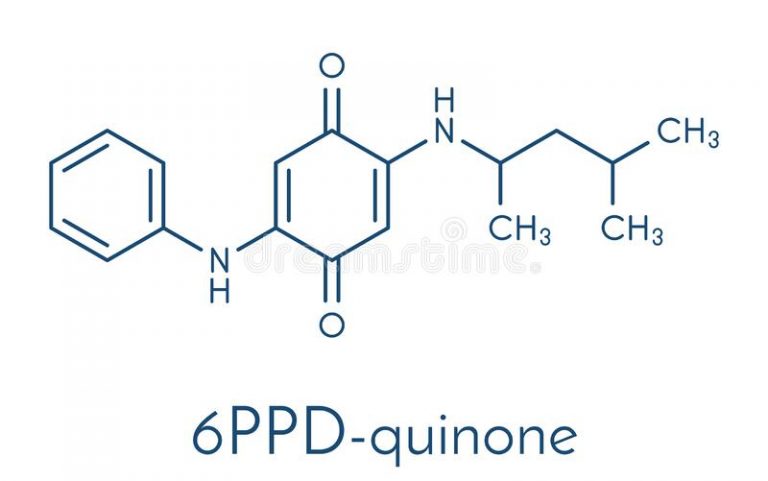

This globally recognized certification is in line with Birla Carbon’s aspiration to achieve net zero carbon emissions by 2050 and the successful introduction of ContinuaTM Sustainable Carbonaceous Material (SCM).