Tyros B.V., a company focused on the recycling of end-of-life tyres, is planning to move into a 2-hectare site on the former UCB site in the port area of Ostend

The start-up will use advanced technologies to process tyres in a sustainable way. Tyros, founded in May 2024, is investing in an electric pyrolysis reactor with the support of the Flemish government (1 million euros in strategic ecology support).

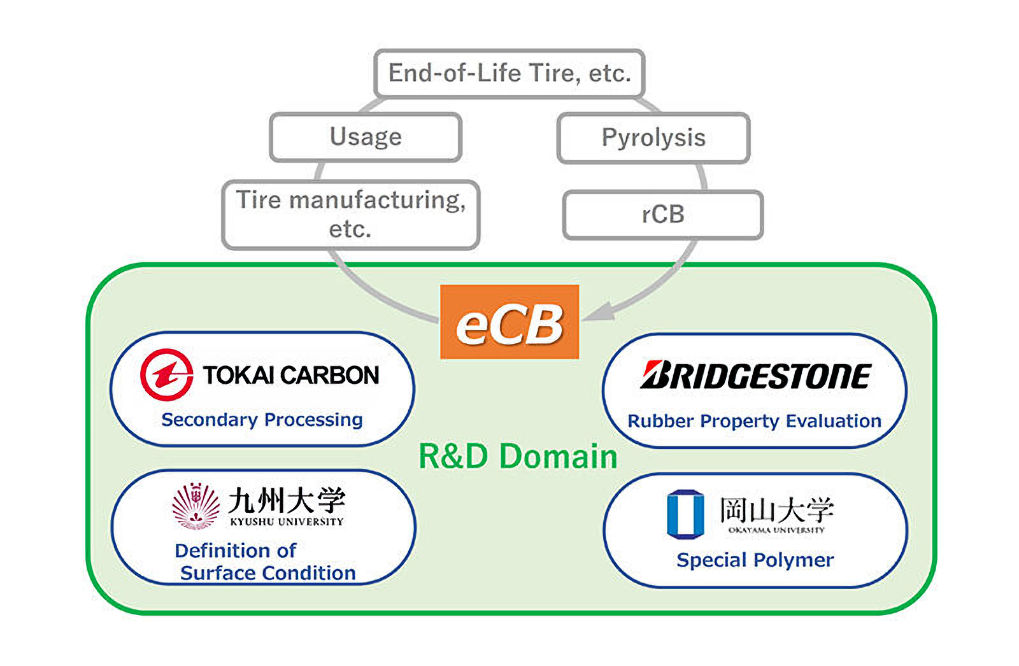

This reactor will convert 9,125 tons of rubber granulate annually into valuable primary components such as recovered Carbon Black, pyrolysis oil and syngas. These raw materials find their way to various sectors, including petrochemicals, automotive, ink production and energy.

The use of this technology is claimed to prevent the emission of almost 21,000 tons of CO2 annually, compared to the traditional combustion of rubber granulate.

In the long term, the site will process 100,000 tonnes of tyres annually, of which 18,000 tonnes via on-site pyrolysis, resulting in the production of 5,000 tonnes of pyrolysis oil and 6,800 tonnes of recovered Black Carbon, crucial raw materials for circular applications. It is worth noting that 100,000 tonnes annually is very close to the total tyre arisings generated in Belgium. (ETRMA figures for 2016 show Belgian arisings at 87,000 tonnes, allowing for growth, 100,000 tons may be more than Belgium produces). With Bolder Industries also looking at a large scale plant in Antwerp, there could be some interesting developments if both come to fruition.

Tyres will be delivered by truck, while shredded tyres will be transported by container via the waterway for further processing, including via a feeder service between Ostend and Antwerp. This sustainable logistics model contributes to maritime traffic in the port and strengthens the circular economy in the region.

Tyros will directly and indirectly create dozens of new jobs.