Tana says repairs and maintenance within the normal life cycle of the machine enables it to work as efficiently as possible during its planned service life. Rebuilding, on the other hand, aims to give it a second life

In solid waste processing, there is a growing need to rebuild machines. Tana Second Life significantly extends the life cycle of machines, while at the same time reducing the consumption of materials needed to manufacture new machines, cutting waste and minimising emissions.

Tana is currently testing how to sustainably and profitably double the life of the machine – in other words, how to give the machine a second life.

Rebuilds offer both financial and environmental benefits

The timely refurbishment, rebuild or upgrade of the main components of a compactor or shredder, mainly the powertrain, offers both financial and environmental benefits. When the diesel engine and the main hydraulic components reach the end of their intended service life after 10,000 operating hours, they must either be completely refurbished or replaced.

Based on a condition assessment, it is possible to calculate in advance when a rebuild is feasible. Using data to predict maintenance is already a reality, since today’s machines are already compatible with remote diagnostics. Knowing all the pressures and fault warnings, the need for refurbishments can be assessed in advance.

Remote monitoring produces data not only about operating hours but also about how hard the machine has been used. When a sufficient amount of data is accumulated, the estimate of the need for refurbishing and costs becomes more precise.

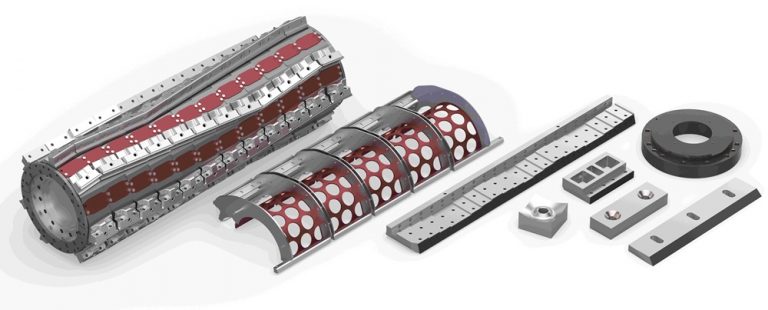

Modular design simplifies rebuilds

Tana’s product development and production have always focused on the longest possible service life and easy maintenance. Making it easier to replace components and anticipate maintenance needs means less materials that need to be replaced at once. In this way, the downtime can be as short as possible.

The modular design of TANA machines also simplifies rebuilds, as entire units can be changed. In the future, it will even be possible to replace the diesel engine with an electric powertrain.

Certified partners and processes ensure reliability

In practice, rebuilds are carried out by partners certified by Tana according to a common operating model. High-quality components and certified processes ensure that rebuilt machines retain their original performance.

The first partner, Humdinger Equipment Ltd in the USA, has already completed several rebuild projects with Tana. In North America, machines undergo up to two full-scale rebuilds during their lifetime, so they even get a third life.

New network partners are starting to be certified in Europe as well. Tana has itself done rebuilds together with its network partners, and several projects are currently in progress.

Sustainable and profitable circular economy

Rebuilds must be justified not only in terms of the climate and the environment but also financially. They must be profitable for owners, as well as for Tana and its rebuild partners.

Although the proportions of recyclable components vary, rebuilding is a significantly cheaper option than purchasing a new machine. The difference to a new purchase can be in the range of 30 to 70 per cent, depending on the age of the machine and the level of refurbishment.

During the rebuild, the machine’s valuable chassis structures are preserved. The owner of the machine gets guarantees for the main components that are replaced, as well as the opportunity to purchase an extended warranty.

When the need for a rebuild is systematically anticipated and the rebuild is carried out as planned, significant savings can be made in investment costs. The contractor’s productivity also increases when there are even fewer disruptions in production, or they are kept short.

Tana also has a clear plan for its products that provides a way to handle the final phase of their life cycle with the least possible burden on the environment.

Company has a separate recycling and refurbishment programme for main components, such as diesel engines. End-of-life machines consist mostly of steel components that can be sold for metal recycling, while some components can also be recovered as spare parts.

Tana is growing in the heart of the circular economy

Tana wants to be closely involved in the circular economy, which involves precisely extending the life cycle of devices. Rebuilding reduces the environmental and social costs of machine manufacturing. It is fundamentally a local operation that reduces the carbon footprint of international transport and keeps support and service close to the customer.

Although Tana’s products do not require rare earth metals, extending the life cycle of machines by rebuilding reduces waste and saves limited natural resources. For example, steel production is still energy-intensive and a major source of climate emissions.

“Tana Second Life rebuild programme is a concrete step in Tana’s transition towards a circular economy. Rebuild operations in accordance with sustainable development are also an essential part of our company’s growth story,” emphasises Kalle Saarimaa, CEO of Tana.

Aiming for a circular economy, Tana continues to develop and produce new, more energy-efficient machines, but it can also conduct profitable business by refurbishing parts and equipment. The share of maintenance and spare parts in the circular economy is increasing.