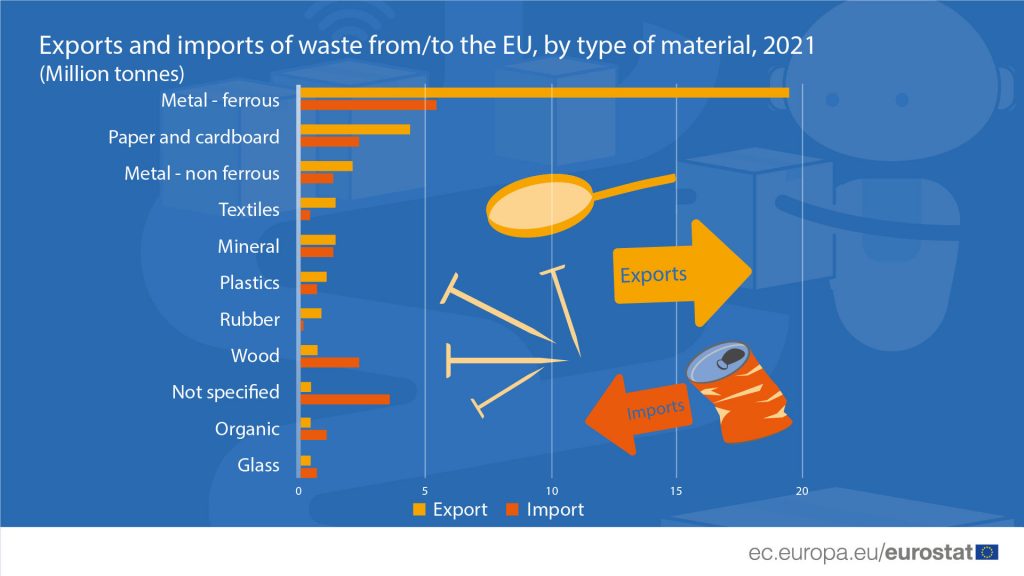

The EU has been working towards a greener economy, and the shipment of waste has been an issue that has needed clarification

There is some evidence that there has been some trans-European movement of waste for disposal. Much of the evidence is anecdotal, some is well known. In the case of tyres, despite almost all EU states having some form of EPR in place, there have long been stories of trans-shipment of waste tyres for disposal in less well managed states.In essence, waste from the West has tended to migrate to the East for disposal.

The EU has agreed on proposals to control the shipment of waste inside Europe, effective from the 27th February.

The text of the rule bans the shipments of all waste destined for disposal within the EU, except if consented to and authorised under the strict conditions of the prior written notification and consent procedure (‘PIC’) and in well-justified cases. On the other hand, intra-EU shipments of waste for recovery operations will continue to be allowed following the less stringent procedure set out in the general information requirements (‘green-listed waste’).

The text of the agreement contains a derogation for shipments of waste explicitly destined for laboratory analysis and experiments if such waste does not exceed 250 kg. In this case, the shipment of such waste will need to follow the general information requirements outlined in the regulation.

The system will be controlled through a EU managed digital central registration system.

The export of waste to non OECD counties willrequire that waste management facilities in third countries, such as Pakistan or India, for example, should be audited by independent bodies. These audits would have to prove that the facilities treat waste in an environmentally sound manner and operators would only be allowed to export waste to these facilities if this were the case.

The new rules require the Commission to establish a register that contains up-to-date information on facilities that have been subject to an audit to help waste exporters prepare for shipments.

What does this mean?

For someone shipping tyres for disposal in Europe, they will have to show that there is a legitimate destination for recovery or recycling, rather than landfill. Technically, this formalises what should have been the case if all players complied with The Basel Convention.

It should bring about an end to the transhipment of waste in Europe, for disposal. Which anecdotally still happened with tyres.

The auditing and registering of third country recipients for recycling and recovery, is actually enforcing the concept behind the much-ignored Annex VII.

The success of these new rules will only be seen in due course. They will rely upon legitimate auditing of third party ricipients – and the old question arises – Quis custodiet ipsos custodes?

How does this impact upon EU recyclers?

The first things that it could do, if fully enforced, is remove much of the rogue element of recycling, and however much the EPR schemes protest, there are rogue operators in almost every market. However, that requires full enforcement throughout Europe.

There is an idea that these waste trans-shipment rules will reduce export demand, and as such create a lower feedstock supply to European recyclers – more tyres retained means lower costs to acquire feedstock – in theory. However, the corollary might also be true, oversupply of feedstock and a shortage of processing capacity could lead to increased costs as those needing to have tyres collected have to pay a higher fee when the piper calls the tune.

There is a real need, across Europe, for the tyre recycling sector to see investment and support. The EU needs to help the players build a recycling sector fit for the circular economy, and whilst the management of the feedstock is one area that needs attention. The creation of demand for the end products is another that lags behind the existing capacities.

Does this impact non-EU members?

For the UK, it can be pretty certain that it will make no difference, unless the EU also decide to apply these rules to temporarily imported wastes, ie waste in transit. The UK government appears to be inn no rush to manage waste tyres more effectively. The UK government adheres to the idea that if the waste is not piling up in the UK, it is not a UK problem.

Could it impact destination markets?

It might have a positive impact on shipping tyres to some destinations where their standards are closer to the EU regulations. They may find that there is more demand for their recycling services if, for example, another third country’s industry is unable to meet EU standards. It is speculation, but if standards in some current destinations are as low as we are led to believe, then the supply of tyres from Europe to those markets may slacken, creating, depending upon how it is considered, a driving force to improve standards, or a motivation to fully exploit the domestic tyre arisings.