The lack of action by government on the T8 may be negated by Mandatory Waste Tracking

Almost sneaking up on the unwary is Mandatory Waste Tracking. The European Union is making more noise about waste tracking and end of waste rules, but it is happening here in the UK too.

The government says; “Mandatory digital waste tracking will help businesses and government move towards a circular economy by joining up and digitising currently fragmented systems to provide a single comprehensive way of tracking the amount and type of waste being produced and where it ends up.

“This will also support the effective regulation of waste, transforming the way environmental regulators monitor compliance, prioritise regulatory activities and help prevent waste crime, including fly tipping, deliberate misclassification of waste, illegal waste exports and the operation of illegal waste sites. It will also facilitate a more level playing field for legitimate waste operators.

“It forms part of the UK government’s wider plans to introduce smarter regulation to grow the economy. Smarter regulation is about improving regulation and guidance for businesses across the board, ensuring it is as clear, proportionate and does not unnecessarily impose burdens on businesses which restrict innovation and growth.”

That is the aim, but then again, the Environment Agency promised that the T8 Exemption was going, and now DeFRA says it is not a priority and will not be dealt with in this parliament. That lack of action means that the proposal to remove the T8 will come before a new government after the election. Tyre and Rubber Recycling wrote to all the environment spokespeople for all the main parties, including the Greens, asking about their stance on the removal of the T8 – none responded.

So, if the government is not willing to act on the T8 Exemption abuses, then how can id say with any confidence that Mandatory Waste Tracking will be in place by 2025?

The answer is that the government already has the ability to introduce Mandatory Waste Tracking through the Environment Act 2021, which provides the powers to introduce mandatory digital waste tracking regulations (clauses 34CA and 34CB of the Environment Protection Act 1990). These regulations can place requirements on relevant waste controllers, or a waste authority, to enter certain information related to the tracking of waste into the waste tracking service.

The government will also be making a range of legislative amendments across the United Kingdom, including (but not exhaustively limited to) legislation relating to the waste duty of care, hazardous waste, trans frontier shipments of waste, waste permitting and licensing and in Wales the statutory use of WasteDataFlow by local authorities. The waste duty of care codes of practice will also need to be revised.

All of this, somewhat ironically, parallels the actions being taken in the European Union.

Let’s hypothesise how this might impact tyres, presuming they are included in the Mandatory Waste Tracking process.

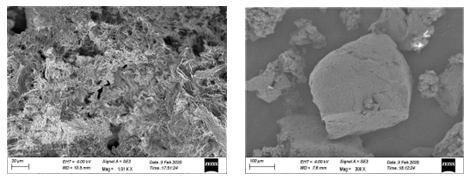

Currently, a tyre becomes waste when it is removed from a vehicle at the end of its intended life. The tyre retailer removing that tyre has, in all but very few exceptions, a duty of care to dispose of that waste tyre by legitimate routes. All carriers and processors should have the appropriate licences. However, it is evident that some collectors are taking tyres at rock-bottom prices – even free of charge, baling them and shipping them out for a quick turnover. That is if they get to be baled in the first place. There are still frequent reports of fly tipped tyres across the UK.

In theory, the retailer is supposed to check that his tyres are going to a legitimate disposal, he should check the collector, the destination, the processor and so on. Most don’t.

The problem with end-of-life tyres is that no-one knows exactly what happens to them. Mandatory Waste Tracking should deal with the issue, though it will need co-operation between various actors in the system.

A tyre retailer’s waste will need to closely match his purchases, essentially, one tyre in means one tyre out. So, he will have to record waste leaving the premises against unit purchases – else the whole system has a huge loophole. He will no longer be able to simply pass waste to the man in a van, for that waste will have to be tracked through collection to processing, to end of waste, or export.

There will be considerable IT challenges and there will need to be a complete recording of every tyre outlet in the country, of which there may be as many as 10,000 from underneath-the-arches part worn sales to equity chains and car dealerships.

If the IT system can be correctly established; if sources of arisings are thoroughly registered, and if everyone plays by the rules, then Mandatory Waste Tracking will go a long way towards minimising tyre related environmental crimes. It may help deal with illegal waste exports. It may negate the need to end the T8 Exemption.